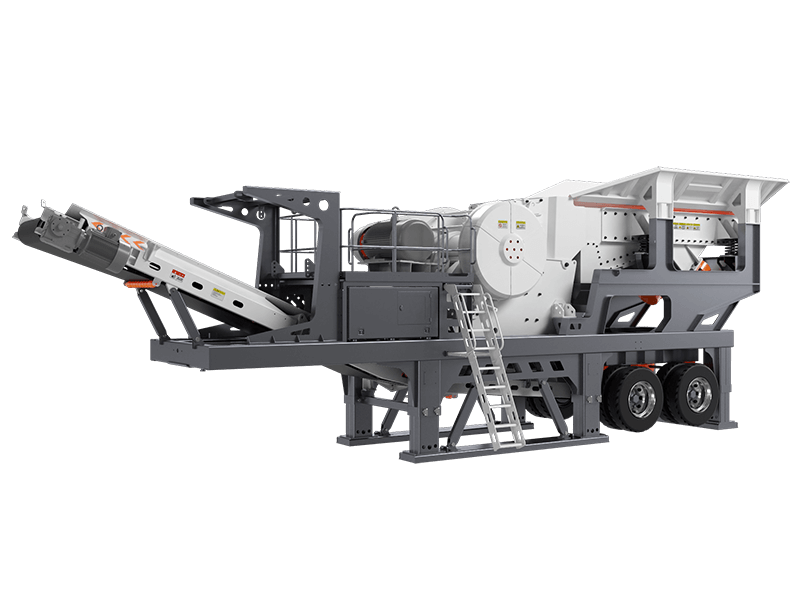

Wheel-Mounted Portable Crusher

Capacity: 80-300t/h

Input size: ≤750mm

SUNJEESPOM has been dedicated to the crushing and screening of natural stone, metal and non-metal mines, municipal construction waste and other industries. The expertise and knowledge accumulated in the process of long term research and development, production and provision of services enable us to provide global customers with the most advanced product solutions in the industry today.

Wheel-mounted mobile crusher plant is the main product of SUNJEESPOM Machine in recent years, which is a fusion of our own research and development and the advanced concept of similar products in China. Perfect craftsmanship and high standard quality inspection is the quality assurance of each piece of equipment. The processing capacity of the Wheel-mounted mobile crusher station is 70-300 tons per hour, and the biggest advantages of this series of products are: flexible movement, convenient installation and commissioning, high degree of intelligence, and fast production.

The Wheel-mounted jaw mobile crusher, also known as the Portable Jaw Crush Plant, is a primary crusher for crushing soft and hard rock in aggregate production. Wheel-mounted jaw mobile crusher plant is a mobile crushing plant with jaw crusher as main machine, and the crushing function is mainly for coarse crushing of large ores. The equipment adopts the integrated structure design, which can be operated as a stand-alone machine or combined with the fine crushing mobile crushing plant to form a mobile crushing station, which is convenient to move and has high production efficiency.

Coarse jaw crushing plant is equipped with grate feeder, double-channel hopper, side outlet belt conveyor, which is convenient for customers to remove soil according to their material characteristics.

The Wheel-mounted jaw mobile crusher hopper volume of 6.5M³, wider feed baffle up to 8M³, can be adjusted to feed the speed of feeding, feeding storage capacity, feeding uniformity and flexibility.

Mobile crusher station special jaw crusher backpack motor space-saving, stable quality, delivery without dismantling, can be shipped as a whole vehicle

Wheel-mounted jaw mobile crusher plant are equipped with tracked boots and built-in hydraulic outriggers, which enable them to quickly gather up and transfer to the site, and automatically and quickly enter the operation mode.

It can be transported as a whole, or dismantled and loaded into containers for transport, and it is convenient for delivery and transport;

The operating site only needs to be levelled and compacted to meet the operating conditions, without the need for hardening and levelling of concrete foundations, which reduces the cost of foundation construction.

Materials are feed to the jaw crusher evenly and gradually by vibrating feeder for primary crushing. And then the crushed materials will be transferred to circular vibrating screen to form a closed-circuit system for cycle crushing. The finished materials will be transferred out by belt conveyors. This is a continuous crushing operations. And the circular vibrating screen can be removed according to the actual production demands, just to crush raw materials directly for primary crushing. So that it will be convenient and flexible to work together with other assorted crushing machines.

| Model | K3-C96-2C | K3-C106-2C | K3-C116-2C | K3-C110-2C |

| Vibrating Feeder | ZSW9638 | ZSW1142 | ZSW1349 | ZSW1349 |

| Jaw crusher | C96 | C106 | C116 | C110 |

| Main belt conveyor | B800 | B1000 | B1200 | B1200 |

| Iron Remover | B800 | B1000 | B1200 | B1200 |

| Side exit belt conveyor | B500x3m | B500x3m | B650x3m | B650x3m |

| Capacity | 80-150TPH | 100-200TPH | 215-275TPH | 200-300TPH |

| Input size | 480mm | 600mm | 700mm | 750mm |

| Weight(t) | 32 | 49 | 53 | 55 |

| Working size (L*W*H mm) | 12000*3400*4000 | 12691*3465*4298 | 14903*5307*4584 | 14903*5307*4658 |

The equipment adopts the integrated structure design, which can be operated as a stand-alone machine or combined with the fine crushing mobile crushing plant to form a mobile crushing station, which is convenient to move and has high production efficiency.

Email is required.