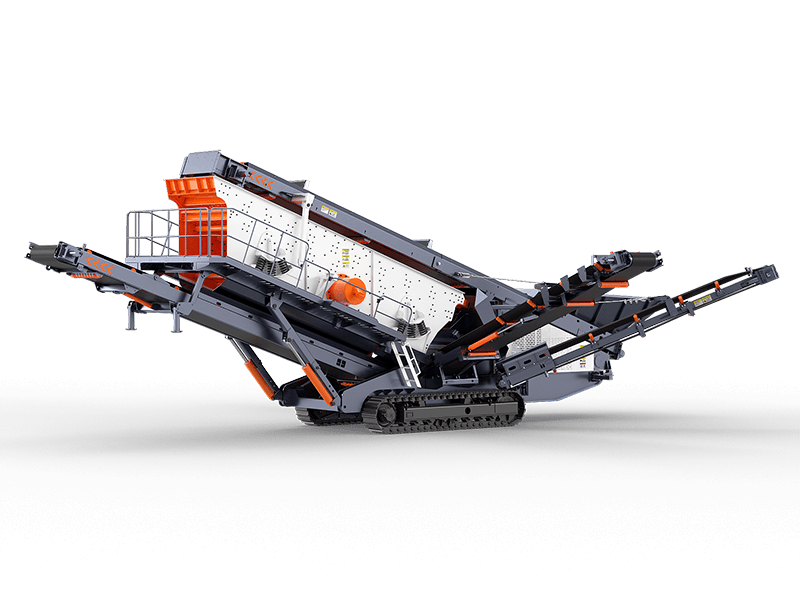

Track-Mounted Mobile Crusher

Feeding Size: ≤200mm

Capacity: 65-720t/h

Track-mounted Screening Plant utilizing high efficiency inclined vibrating screen boxes; offering exceptional output capacity and accurate separation for screening either sand, gravel, aggregate or recycled/demolition materials.

Robust tracks ensure excellent on site positioning and mobility together with operational stability.

Variable speed forward and side product conveyors are hydraulically operated and easily stowed for transport.

Robust and durable screens featuring rapid setup times.

High volume, high efficiency product screening.

Versatile in a wide range of applications.

Easily accessible maintenance and spare part, simple hydraulic circuits.

Maximum mobility with heavy duty, low ground pressure crawler tracks (track).

The material is transported to the crushing equipment through the belt conveyor, and the crushed material falls into the belt conveyor and is sent out. Qualified materials are either sent out from the hopper or stacked by the belt conveyor under the vibrating screen, and the unqualified large materials are directly sent back to the crushing chamber of the crusher for further crushing.

| Model | TS1860 | TS2160 |

| Vibrating Screen Model | 3YZK1860 | 3YZK2160 |

| Maximum feeding size | <200 | <200 |

| Capacity | 65-586t/h | 81-720t/h |

| Motor Power | 22KW | 30KW |

| Feeding belt conveyor Model | B1000x11.8m | B1000X11.8m |

| Generator | 360KW Generator | 500KW Generator |

| Electrical System | Screen display engine operation parameter monitoring, track walking, and remote control of each belt conveyor for operation | Screen display engine operation parameter monitoring, track walking, and remote control of each belt conveyor for operation |

Tracked vibrating screens utilizing big volume hopper, offering exceptional output capacity and accurate separation for screening either sand, gravel, aggregate or recycled/demolition materials.

Email is required.