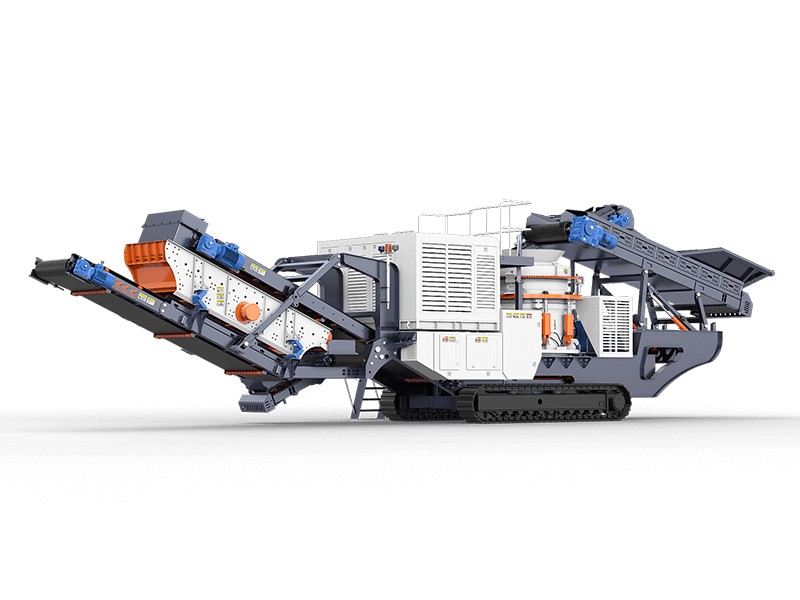

Track-Mounted Mobile Crusher

Feeding Size: 50-200mm

Capacity: 90-630t/h

SUNJEESPOM track-mounted Cone Crusher is designed for mobility and versatility in a wide range of applications from quarrying and rock excavation to construction projects.

Our tracked mobile multi-cylinder hydraulic cone crusher is a fully automatic crusher with high degree of intelligence and automation. The design of fully hydraulic chassis, and self-powered system makes it possible to command the road walking by remote control, commonly used in hillside and rugged roads, with strong power, suitable for slope climbing operation. They are among the most versatile and trusted cone crushers on the market.

Our tracked multi-cylinder hydraulically adjustable cone crushers are suitable for crushing mid-hard and above mid-hard ores and rocks, each of our models can crush aggregates to almost any size, and can be flexibly applied in secondary and tertiary crushing, featuring high productivity, excellent product shape, and being as robust and easy to service as they are powerful.

All models are compatible with each other so they are suitable mainly in the linking with primary crushers and screening plants., as well as being equally productive working as stand-alone units.

It is therefore the right choice for customers who demand high quality equipment and products, and who want to realize the convenience of frequent site relocation.

Powerful Deutz or Cummins engine ensures abundant power output.

Truck-mounted screening machine has a screening area of up to 8 square meters, single or double-deck screen to meet different discharge options.

Optimized design, the whole machine is compact and can be transported by road.

Powerful automatic control system to ensure easy operation.

Materials are evenly transported to cone crusher by vibrating feeder, after cone crusher makes primary crushing, a cycle system forms by circular vibrating screen, materials get cycle crushing, finished products are output by belt conveyor and continuous crushing operations go. Mobile cone crusher plant can remove circular vibrating screen based on the actual production, materials are directly made primary crushing, equipped with another crushers, it is convenient and flexible to operate.

| Model | THP300L | THP400L | TCH430 |

| Feeding Machine | |||

| Specification | B1000*4.6m | B1200*4.6m | B1000*6.5m |

| Drive Mode | Inverter motor | Inverter motor | Inverter motor |

| Reducer drive | Reducer drive | Reducer drive | |

| Cone Crusher | |||

| Equipment | HP300 | HP400 | CH430 |

| Max Feeding Size | 200mm | 260mm | 185mm |

| Minimum Outlet | 10mm | 20mm | 20mm |

| Motor Power | 220KW | 280KW | 160KW |

| Frame | |||

| Hydraulic Tracked Chassis | 60T | 60T | 60T |

| Boat Frame | Q345B Welding | Q345B Welding | Q345B Welding |

| Return screen | |||

| Specification | 2YZK1500*3500 | YK1500*3800 | YK1530 |

| Drive Mode | Vibration Motor 3.7KW | Vibration Motor 3.7KW | Vibration Motor 3.7KW*2 |

| Main Belt Conveyor | |||

| Specification | B1200*12.5m | B1200*10.6m | B1200*10.6m |

| Drive Mode | Motor reducer drive 15KW | Motor reducer drive 15KW | Motor reducer drive 15KW |

| Looped polyester canvas strap | EP300-B1200x5(6.5+1.5) | EP300-B1200x5(6.5+1.5) | |

| Under the screen belt conveyor | |||

| Specification | B1200*5.6m | B1200*6.2m | B1200*5.4m |

| Drive Mode | Motor reducer drive 7.5KW | Motor reducer drive 7.5KW | Motor reducer drive 7.5KW |

| Looped polyester canvas strap | EP300-B1200x3(4.5+1.5) | EP300-B1200x5(6.5+1.5) | |

| Return belt conveyor | |||

| Specification | B500*12.5m | B650*12.5m | B500*12.5m |

| Drive Mode | Motor reducer drive 7.5KW | Motor reducer drive 7.5KW | Motor reducer drive 7.5KW |

| Looped polyester canvas strap | EP300-B500x3(4.5+1.5) | EP300-B500x3(4.5+1.5) | |

| Transfer Belt Conveyor | |||

| Specification | B500*2.4m | B650*2.4m | B500*2.4m |

| Drive Mode | Motor reducer drive 4KW | Motor reducer drive 4KW | Motor reducer drive 4KW |

| Looped polyester canvas strap | EP200-B500x3(4.5+1.5) | EP200-B650x3(4.5+1.5) | |

| Power System | |||

| Generator Set | 400KW Generator Set | 500KW Generator Set | 305KW Generator Set |

| Electrical System | |||

| Electric control cabinet | The cone crusher motor starts with variable frequency, the feeder starts with variable frequency, and other motors start directly. | The cone crusher motor starts with variable frequency, the feeder starts with variable frequency, and other motors start directly. | The cone crusher motor starts with variable frequency, the feeder starts with variable frequency, and other motors start directly. |

| Hydraulic system | |||

| Belt conveyor folding cylinder | Hydraulic automatic lift | Hydraulic automatic lift | Hydraulic automatic lift |

| Hydraulic Pumps, Valves, Accessories | Load Sensitive, Electro-hydraulic Proportional Manifold | Load Sensitive, Electro-hydraulic Proportional Manifold | Load Sensitive, Electro-hydraulic Proportional Manifold |

The Track-mounted Cone Crusher provides a high degree of control over the final product, making it the ideal portable secondary crusher for any aggregates producer or contractor looking for a high output capacity machine that provides large reduction ratios and an excellent cubical shape

Email is required.