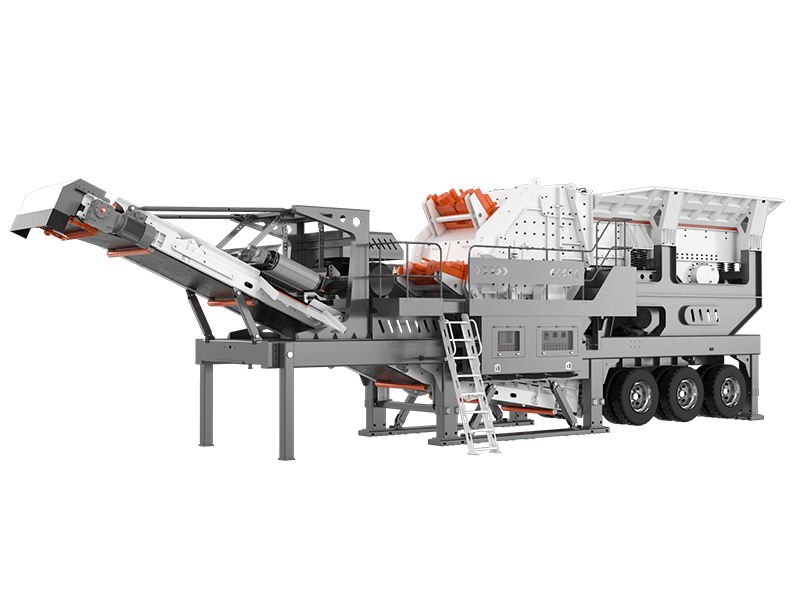

SUNJEESPOM Wheel-mounted Impact Crusher is a portable crushing plant designed by SUNJEESPOM Group for medium crushing and screening, which is mainly used for processing soft rock. It has the general features of stable performance, easy mobility, quick installation, convenient maintenance and integrated electrical control of portable mobile plant, and also provides more diversified modular solutions for users by integrating crushing and screening in one mobile plant. At the same time, because it integrates crushing and screening in one mobile station, it provides users with more diversified modular solutions.

1. Mature technology and pre-designed for fast delivery and quick set-up. Ready-made plant layouts and flowsheets, mature process, short delivery time and easy installation, making the whole crushing plant can be put into operation in weeks instead of months, which can make a faster return on investment.

2. Flexible convenient delivery and transport. The frame adopts the latest structural design, which can be transported as a whole or disassembled and then transported using containers, which is convenient for shipment and transport and provides more choices for customers.

3. No concrete foundation required, reducing infrastructure costs. The crusher is mounted on the chassis, eliminating the need for heavy concrete foundations and steel structures on site, which can significantly reduce infrastructure costs.

4. Wheel-mounted chassis, hydraulic control and boots design, easy to move. The vibrating screen and boots equipped with hydraulic cylinders and are controlled by a hydraulic system, no need for manual connections and handling, making them easy to move and can be re-located by towing with a standard truck in the site.

Materials are fed to the impact crusher evenly and gradually by vibrating feeder for crushing. And then the crushed materials will be transferred to circular vibrating screen to form a closed-circuit system for cycle crushing. The finished materials will be transferred out by belt conveyors. This is a continuous crushing operations. And the circular vibrating screen can be removed according to the actual production demands, just to crush raw materials directly for primary crushing. So that it will be convenient and flexible to work together with other assorted crushing machines.

| Model | K3-PF1214-2C | K3-PF1315-2C |

| Capacity | 80-150tph | 100-200tph |

| Maximum feeding size | 300mm | 350mm |

| Power of the impact crusher | 132kw | 200kw |

| Operation weight | 45t | 49t |

| Operation Dimensions(L*W*H) | 14740*4945*6803mm | 14740*4945*6803mm |

| Model | K3-LF150-2C | K3-LF250-2C | K3-LF350-2C |

| Vibrating feeder | GZD9638 | GZD1142 | GZD1349 |

| Impact crusher | LF150 | LF250 | LF350 |

| Maximum feeding size | 500mm | 700mm | 800mm |

| Capacity | 80-150tph | 100-200tph | 200-400tph |

| Power of the impact crusher | 160kW | 250kW | 315kW |

| Operation weight | 32t | 49t | 51t |

| Operation Dimensions(L*W*H) | 11900*4385*4098mm | 12691*4485*4298mm | 15350*6025*4500mm |

Because it integrates crushing and screening in one mobile station, it provides users with more diversified modular solutions.

Email is required.