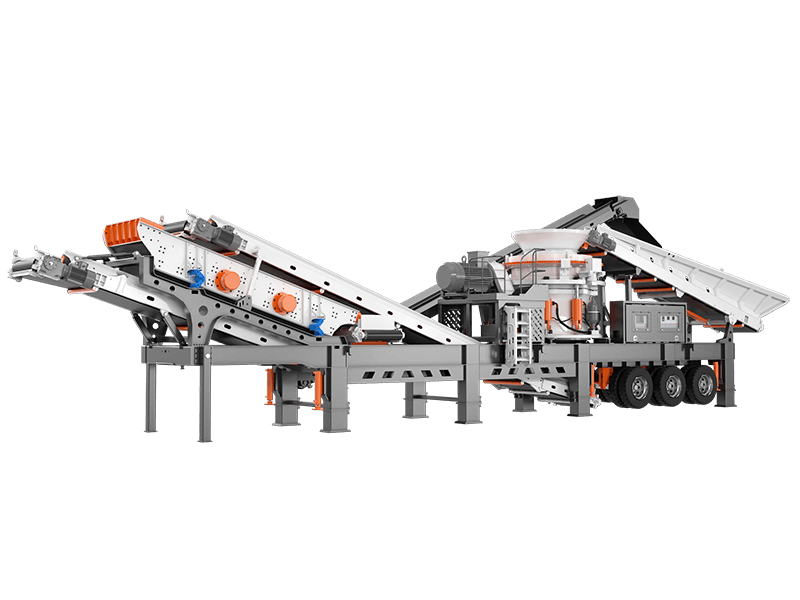

Wheel-Mounted Portable Crusher

Capacity: 48-630t/h

Max Feeding size: 310mm

Wheel mounted mobile cone crusher also called wheeled cone crusher,K3 series mobile cone crusher is our new generation products,easy to install and flexible to move, achieving standardization, universality and modularization to a greater extent,it is designed for secondary/tertiary crushing and screening purpose,it is an ideal equipment for crush medium hard to hard stone for quarry aggregate production,as well as the raw material process in mining field.

1.K3-C1 and K3-RS-2C’s feeding belt has an adjustable speed and can feed materials evenly. It is equipped with a 4.5m³ transfer feeding silo and has the function of transferring and storing materials to ensure sustainable and uninterrupted operation and is more energy-saving.

2.The hopper can be loaded with a loader to ensure a variety of flexible feeding; it solves the problem of idle materials participating in the crushing process.

3.The main equipment adopts hydraulic cone crusher, which can be equipped with return screening equipment to become an independent crushing unit to meet various combinations of customers.

4.The working site only needs to have the road surface leveled and compacted to achieve working conditions. there is no need for cement foundations, after the station layout, the hydraulic cylinder legs are extended to quickly enter the working mode.which greatly reduces costs.

5.The mobile chassis and all equipment can load into container,avoid bulk ship/roll ship transportation, save a lot shipping cost,protect machine from sea corrosion.

6.The belt conveyor are vehicle-mounted,minimize on-site installation work,also easier move to other project site.

7.The frame and tire module adopt a modular design, which can quickly switch between frame type and tire type; satisfying customers' multiple choices.

According to different crushing stages and application fields, we provide the following three series of mobile cone crushers for customers to choose from.

When working, the materials are evenly transported into the crusher by the feeder. After the crusher performs preliminary crushing, a closed-circuit system is formed by the circular vibrating screen to realize the cyclic crushing of the materials, and the finished materials are output by the conveyor for continuous crushing operation. The mobile jaw crusher can remove the circular vibrating screen according to the actual production needs, and actually firstly crush the material directly, and it is flexible and convenient to use in conjunction with other crushing equipment.

| Model | K3-HP200-1C | K3-HP300-1C | K3-HP400-1C | K3-CH430-1C | K3-CH440-1C | K3-CS160-1C |

| Cone crusher model | HP200 | HP300 | HP400 | CH430 | CH440 | CS160 |

| Belt feeder | B800 | B1000 | B1200 | B800 | B1000 | B1000 |

| Capacity Potential(t/h) | 90-250 | 115-440 | 140-630 | 48-345 | 90-605 | 109-349 |

| Max feeding size(mm) | 235 | 240 | 310 | 235 | 300 | 115 |

| Weight(t) | 31 | 37 | 47 | 27 | 32 | 39 |

| Transport dimensions(mm) | Disassemble and ship | Disassemble and ship | Disassemble and ship | Disassemble and ship | Disassemble and ship | Disassemble and ship |

| Working dimensions(mm) | 14080*2678*4359 | 14080*2678*4859 | 14080*2678*4859 | 14080*2678*5159 | 14080*2678*5359 | 14080*2678*5059 |

| Model | K3-HP300-2C | K3-CH430-2C | K3-CS160-2C |

| Cone crusher model | HP300 | CH430 | CS160 |

| Vibrating screen model | 3YZK2160 | 3YZK2160 | 3YZK2160 |

| Capacity Potential (t/h) | 115-440 | 48-345 | 109-349 |

| Max feeding size (mm) | 230 | 235 | 115 |

| Weight(t) | 55 | 50 | 62 |

| Transport dimensions(mm) | Disassemble and ship | Disassemble and ship | Disassemble and ship |

| Working dimensions(mm) | 15143*3869*7060mm | 15143*3869*7360mm | 15143*3869*7260mm |

| Model | K3-HP200RS-2C | K3-HP300RS-2C | K3-HP400RS-2C | K3-CH430RS-2C | K3-CH4400RS-2C |

| Cone crusher | HP200 | HP300 | HP400 | CH430 | CH440 |

| Belt feeder | B800 | B1000 | B1200 | B800 | B1000 |

| Return screen | YK1530 | YK1640 | YK1750 | YK1530 | YK1640 |

| Capacity Potential(t/h) | 90-250 | 115-440 | 140-630 | 48-345 | 90-605 |

| Max feeding size (mm) | 235 | 240 | 310 | 235 | 300 |

| Weight(t) | 50 | 56 | 65 | 46 | 51 |

| Transport dimensions(mm) | Disassemble and ship | Disassemble and ship | Disassemble and ship | Disassemble and ship | Disassemble and ship |

| Working dimensions(mm) | 21700*3888*5150 | 21700*3888*5950 | 21700x4500x5950 | 21700*3888*6250 | 21700*3888*6450 |

The working site only needs to have the road surface leveled and compacted to achieve working conditions. there is no need for cement foundations, after the station layout, the hydraulic cylinder legs are extended to quickly enter the working mode.which greatly reduces costs.

Email is required.