The 5X vertical shaft impact sand making machine is a new generation of high-efficiency and energy-saving crusher developed and produced by our company by introducing foreign technology and combining the advantages of similar domestic products. Sand making machine, with energy saving, high output, high energy utilization rate, excellent product particle size, easy maintenance and repair, and wide range of applications, to meet the needs of modern sand and gravel production.

This equipment is particularly suitable for providing sand and gravel aggregates for many fields such as high-rise buildings, highway (railway) construction, municipal engineering, large water conservancy facilities, concrete mixing stations, demolition recycling etc. It is a key equipment for artificial sand making, with the ability to run in standard, semi-autogenous and fully autogenous configurations, our models meet the most stringent material specs, allowing you to meet the challenges of any job you face. In mining applications, can be used to prepare feed materials before mills.

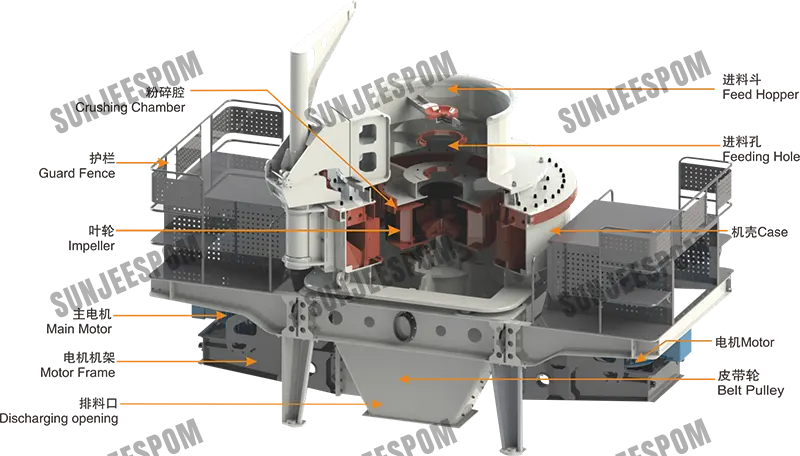

1. Optimized design, high output and efficiency.

Deep cavity rotor after optimized design, the internal more smooth curve shape design, reduce the material flow resistance, so that the material throughput increased by about 30%.

2. Highly wear-resistant and high-temperature-resistant materials, saving production costs.

The core wear-resistant material is made of highly wear-resistant and high-temperature-resistant material used in important industries in the United States. The circumferential guard can be turned up and down for use after partial wear, which improves the material utilization rate and can increase the service life by more than 48%. Combined hammer head design, only need to replace the worn out part of the hammer head, can reduce the use of cost by more than 30%. In addition to increase the vice hammer head, effectively prevent the main hammer head wear damage to the vertical plate.

3. Unique feeding method and crushing form.

Completely centre feeding + stone hitting stone / stone hitting iron, centre feeding accompanied by waterfall falling material + stone hitting stone / stone hitting iron, abandoning the traditional equipment to metal components in the form of crushing materials, the use of high-speed movement of the material is crushed by friction with each other by themselves.

4. Reliable dual-pump oil lubrication system.

Double oil pump complementary system can ensure oil supply, when no oil flow, no oil pressure can automatically shut down, safe and reliable; the use of thin oil lubrication system, but also can reduce bearing friction, increase bearing speed, thus greatly improving efficiency Bearing selection of Japan, Sweden, the United States and other international brands.

5. Special sealing structure at the lower end of spindle ensures no oil leakage without oil seal.

6. Special structure, easy maintenance and replacement parts

Hydraulic cover opening device imported from Japan can move the cover conveniently and quickly, which saves labour and effort in replacing and overhauling the internal parts of the machine body.

| Model | 5X7615 | 5X8522 | 5X9532 | 5X1145 | 6X1150 | 6X1263 | |

| Capacity(t/h) | Cascade and center feeding | 150-280 | 240-380 | 350-540 | 413-442 | 450-545 | 550-640 |

| center feeding | 70-140 | 120-200 | 180-280 | 250-360 | 344-368 | 454-486 | |

| Feeder opening size(mm) | Soft material | 35 | 40 | 45 | 50 | 45 | 50 |

| Hard material | 30 | 35 | 40 | 45 | 55 | 60 | |

| Rotating speed | 1700-1900 | 1500-1700 | 1300-1510 | 1100-1310 | 1000-1300 | 900-1200 | |

| Power of the double motors(kw) | 110-150 | 180-220 | 260-320 | 400-440 | 440-500 | 600-630 | |

| Overall dimension(mm) | 4110x2330x2300 | 4140x2500x2700 | 4560x2600x2900 | 5100x2790x3320 | 5700x2980x4149 | 5500x2750x3950 | |

| Power | 380V:50Hz | ||||||

| oil lubrication station | Power of double oil pump | 2x0.25kw | |||||

| safety | Dual oil complementary oil supply; automatic shutdown without oil flow; water cooling; motor heating start in winter | ||||||

| Overall dimension(mm) | 820x520x1270 | ||||||

| Fuel tank heater power(kw) | 2kw | ||||||

It is a key equipment for artificial sand making, with the ability to run in standard, semi-autogenous and fully autogenous configurations, our models meet the most stringent material specs, allowing you to meet the challenges of any job you face. In mining applications, can be used to prepare feed materials before mills.

Email is required.