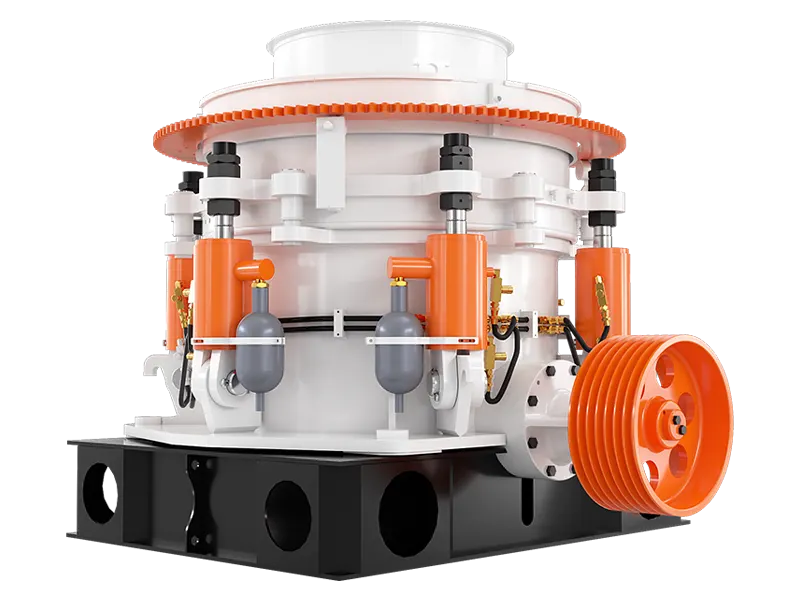

Crushing and Sand Making Equipment

Feeding Size: 33-450mm

Capacity: 90-1200t/h

SUNJEESPOM cone crushers are reliable rock crushing machines for all demanding quarry, mining, and tunneling applications. Over the years they have become the popular modern cone crushers in the world.

SUNJEESPOM has many cone crushers in operation around the world, including the leading HP (multi-cylinder hydraulic cone crusher) and SH (single cylinder hydraulic cone crusher). The knowledge we gain from experience, research and customer feedback is passed on to you in the form of refinements and valuable advice.

Final products for quarries include aggregates for concrete, asphalt and railway ballast.

1/ High crushing efficiency. It adopts the optimal structure of fixed spindle and small spherical axis, the efficiency is 5%-15% higher than the spring cone crusher.

2/Super strong production capacity. The perfect combination of crushing stroke, crushing speed and crushing cavity make its yield 35% - 60% higher than common cone crusher.

3/Perfect finished particles. Using the unique principle of multi-layers crushing, the ratio of cubic particles in the finished product is obviously increased, the flakiness particles are reduced, and the grade is more reasonable.

4/Advanced lubrication mechanism. Multi- point hydraulic lubrication control system can ensure that the equipment bearing lubrication double protection and overload protection.

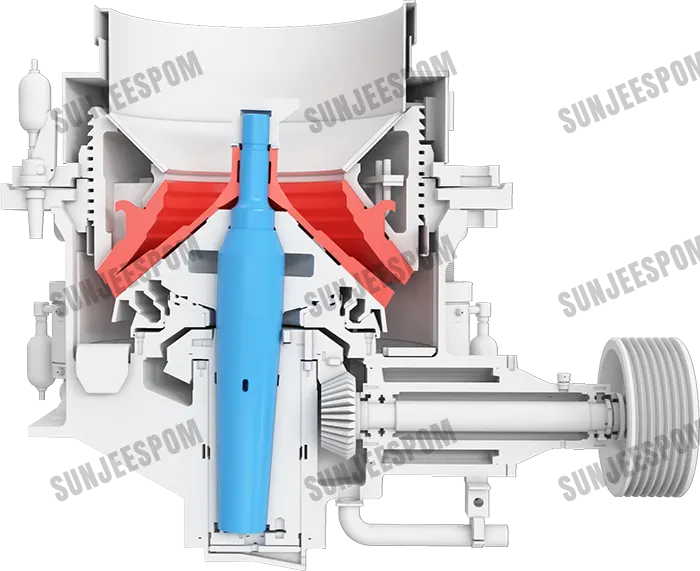

Under the leading role of eccentric sleeve, the movable cone of the HP Series high-efficiency hydraulic cone crusher does rotary and pendulum movement which drives the broken walls squeeze and twist the raw material between the rolling ace tabular wall and it. According to laminated theory, the raw material is crushed and polished following their own texture by the force from different directions. Stable aggregate are produced finally. The eligible raw material falls down from the gap of the broken wall. The others will be kept crushing until it reaches the desired size.

| Model | Cavity Type | Max. Feeding Size(mm) | Side Feeding Size(mm) | Minimum Discharge Opening Size(mm) | Motor power(kW) | Capacity(t/h) | Weight (kG) |

| HP200 | C2 Coarse | 171 | 190 | 19 | 160 | 90-250 | 10400 |

| M Medium | 96 | 120 | 16 | ||||

| F1 Fine | 76 | 95 | 13 | ||||

| F2 Extrafine | 56 | 70 | 8 | ||||

| HP300 | C1 Extra coarse | 219 | 230 | 25 | 220 | 115-440 | 18000 |

| C2 Coarse | 189 | 210 | 20 | ||||

| M Medium | 120 | 150 | 15 | ||||

| F1 Fine | 84 | 105 | 11 | ||||

| F2 Extra fine | 64 | 80 | 8 | ||||

| HP400 | C1 Extra coarse | 276 | 290 | 30 | 315 | 140-630 | 28700 |

| C2 Coarse | 225 | 250 | 25 | ||||

| M Medum | 157 | 196 | 20 | ||||

| F1 Fine | 88 | 110 | 13 | ||||

| F2 Extra fine | 72 | 90 | 10 | ||||

| HP500 | C1 Extra coarse | 314 | 330 | 38 | 400 | 175-790 | 38000 |

| C2 Coarse | 261 | 290 | 28 | ||||

| M Medum | 168 | 210 | 22 | ||||

| F1 Fine | 104 | 130 | 13 | ||||

| F2 Extra fine | 76 | 95 | 10 | ||||

| HP800 | C1 Extra coarse | 334 | 352 | 38 | 630 | 260-1200 | 64100 |

| C2 Coarse | 283 | 298 | 32 | ||||

| M Medium | 220 | 275 | 25 | ||||

| F1 Fine | 184 | 230 | 16 | ||||

| F2 Extra fine | 120 | 150 | 10 |

Multi-cavity configuration to meet different crushing needs

This machine is equipped with multiple cavities for medium crushing and fine crushing. It only needs to replace a small number of parts such as the corresponding cavity lining plate, and then different cavity types can be converted to meet the different crushing needs of users and realize a multi-purpose machine.

Email is required.