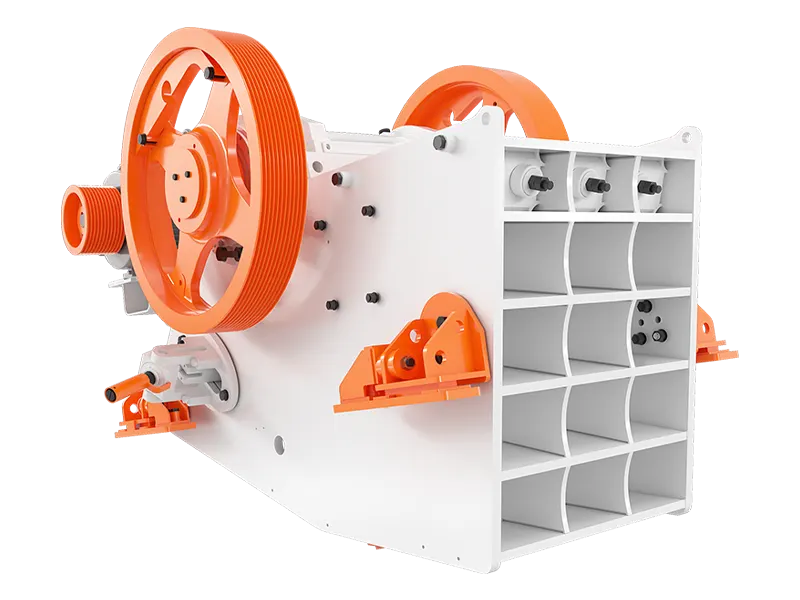

Crushing and Sand Making Equipment

Feeding Size: ≤1070mm

Capacity: 120-1170t/h

SUNJEESPOM SC series jaw crushers serve as primary crushers in aggregates production, mining activities and recycling applications. Adopted latest technology, SC series jaw crusher achieve higher crushing efficiency with less consumption. The deep V-cavity design makes the crushing cavity wear more evenly, prolonging the service life of the jaw plates. The discharge opening can be adjusted by wedge or hydraulically depending on different requirements, which makes the adjustment of chute easier. It has been widely praised by customers for its smaller size, lower consumption, higher capacity and easier adjustment.

20-30mm、10-20mm、5-10mm、0-5mm

It can crush more than 100 kinds of rocks. The common discharge size is...

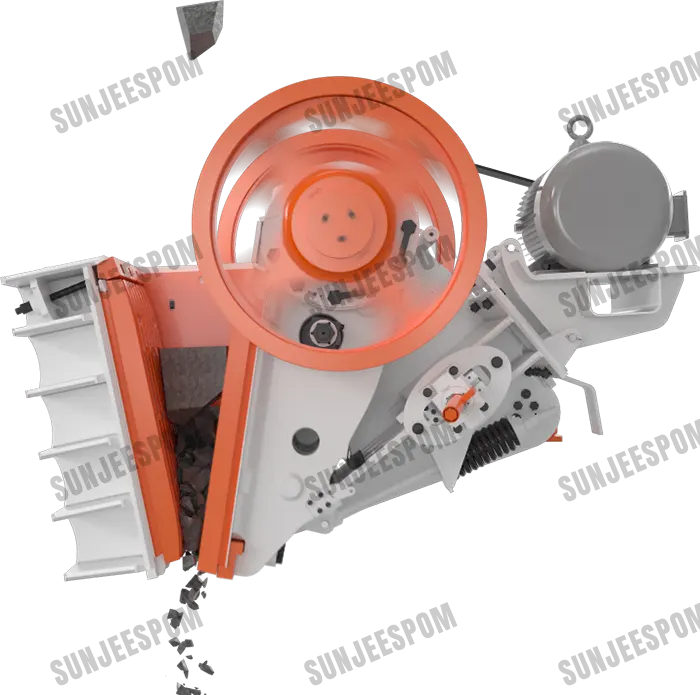

Deep cavity crushing, energy saving

Optimized deep cavity crushing has no dead ends, the feeding capacity and crushing efficiency are greatly improved, the energy saving of single machine is 15%-30%, and the energy saving of system is more than doubled.

Advanced technology and strong crushing force

Using advanced crushing technology and digital processing equipment, the internal structure is precise and the crushing capacity is enhanced.

Easy to maintain and improve production efficiency

The equipment adopts the centralized grease lubrication system, which is safe and reliable, convenient and fast for maintenance, and reduces downtime for maintenance.

Green environmental protection

Low noise, equipped with dust removal device, reduce dust generation, reduce pollution, and strictly comply with national environmental protection standards.

The crushing method of the jaw crusher is a curved extrusion type, which is mainly composed of a frame, an eccentric shaft, a large pulley, a flywheel, a side guard, a toggle plate, a back seat of the toggle plate, a clearance adjustment screw, a return spring, a fixed jaw plate and a movable plate. Jaw plate and other parts. SC jaw crusher is usually driven by motor as the power source. When working, the motor drives the belt and pulley, and the movable jaw moves up and down through the rotation of the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw to approach the fixed jaw, and at the same time, the material is crushed or Chop into pieces to achieve the purpose of breaking. When the movable jaw goes down, the angle between the toggle plate and the movable jaw becomes smaller, the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring, and the crushed material is discharged from the lower part of the crushing chamber. With the continuous rotation of the motor, the crusher performs periodic motion to crush the materials and discharge them to achieve mass production.

| Model | Feeding Size(mm) | Maximum Feed(mm) | Power(kw) | Discharge Size(mm) | Capacity(t/h) |

| SC96 | 930x580 | 490 | 90 | 60-175 | 120-410 |

| SC106 | 1060x700 | 600 | 110 | 70-200 | 165-520 |

| SC110 | 1100x850 | 720 | 160 | 70-200 | 180-540 |

| SC116 | 1150x760 | 650 | 132 | 70-200 | 190-625 |

| SC120 | 1200x870 | 740 | 160 | 70-175 | 190-560 |

| SC125 | 1250x950 | 800 | 185 | 100-250 | 260-775 |

| SC150 | 1400x1200 | 1020 | 220 | 125-250 | 355-900 |

| SC160 | 1600x1200 | 1020 | 250 | 150-300 | 445-1170 |

Higher crushing ratio and efficiency, Easier adjustment with hydraulic system, Lower spare parts consumption.

Email is required.