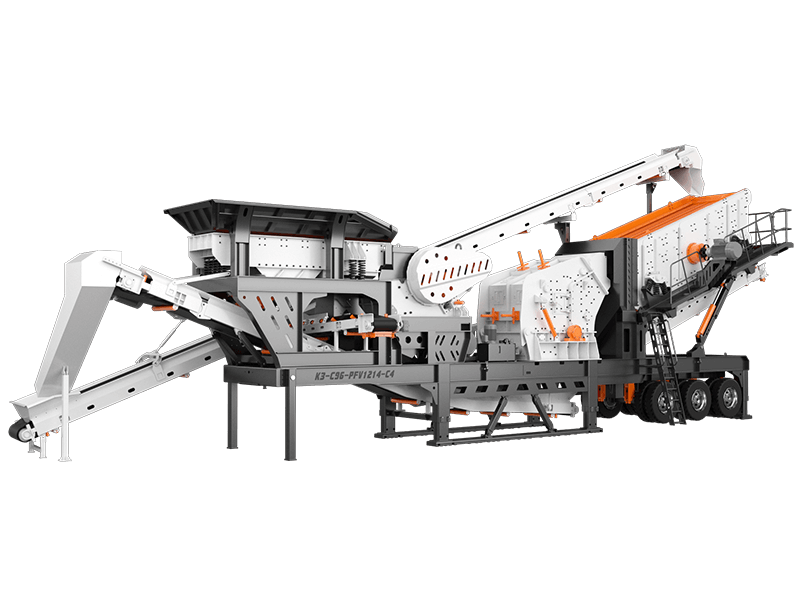

Wheel-Mounted Portable Crusher

Capacity: 80-150t/h

Four-in-one wheel-mounted crushing plant is a new type of mobile crushing equipment, which can supply the customers the best crushing and screening solutions. Considering from the customers’ standpoint, efficiently integrates the feeding equipment, crushing equipment, screening equipment, effectively solving the site constraints of the fixed crushing plants. It not only avoids the site infrastructure, but also expands the material stack space due to the compact equipment layout.

The K3 series portable crushing plant combines a feed hopper and feeder, jaw crusher, impact crusher (cone crusher), three deck inclined vibrating screen with feed and returns conveyors all mounted on the same semi-trailer chassis. This provides a compact and highly mobile solution to any operator needing medium quantities of quality sized aggregates in remote or rural locations.

The feeder and feed hopper supplies material to the main feed conveyor which is discharged onto the three-deck vibrating screen. Unqualified rock from the top screen are crushed by the impact crusher(cone crusher) and returned to the main feed conveyor for further screening. The two lower screen decks produce three graded products.

1. Four-in-one crushing plant are equipped with grizzly feeder, double-pass discharge hopper, and side belt conveyor, which is convenient for customers to remove dust and dirty.

2. The volume of feeding bin is 6.5m³, and the widened feed wall reaches 8m³, which can be adjusted speed, with large feeding storage capacity.

3. The combination of feeder, primary crusher, secondary crusher and vibrating screen forms a complete crushing production line;

4. The crushing plant is fully equipped with track boots. After standing, the electric-hydraulic outrigger extends, and it doesn’t need to manually carry the connecting support seat, automatically and quickly into the operation mode.

5. Vehicle-mounted belt conveyor can be paired with the operation, minimizing the on-site installation and facilitating the site variations

6. Convenient shipping and transport. It can be transported as a whole or loaded into containers.

7. The operating site requires only road levelling and compacting, not a concrete foundation, which reduces the cost of foundation construction.

8. The chassis and tires adopt modular design, which can realize rapid switching between chassis and tires to meet customers' various choices.

A kind of body for 8 models common, feeding unit interchange system, crushing unit interchange system and screening unit interchange system only need to re-invest the cost of stand-alone equipment, within a short period of time, can be realised in the same body of different models of feeding unit, crushing unit and screening unit interchange system, the whole machine between the matching of the various systems, to adapt to the occasion of a wider range of crushing function is more powerful.

| No. | Name | Itme | K3-C96HP200-4C | K3-C96PF1214-C4 | K3-PE57CS110-4C | K3-PE57PF1210-4C |

| 1 | Hopper | Volume | 4m³ | 4m³ | 4m³ | 4m³ |

| 2 | Vibrating feeder | Equipment | GZD3896 | GZD3896 | GZD8630 | GZD8630 |

| 3 | Primary crusher | Equipment | SC96 | SC96 | PE500x750 | PE500x750 |

| 4 | Secondary crusher | Equipment | HP200 | PFV1214 | CS110 | PF1210 |

| 5 | Vibrating screen | Equipment | 3YK1848 | 3YK1848 | 3YK1848 | 3YK1848 |

| Outline parameters of the whole machine | ||||||

| 10 | Working size(L*W*H)mm | 20121x5731x8019 | 20121x5731x7598 | 18079x5146x7823 | 18079x5146x7823 | |

| 11 | Capacity | 100-150 tons/hour | 100-150 tons/hour | 80-120 tons/hour | 80-120 tons/hour | |

| 12 | Weight of the whole machine | 65 tons | 68 tons | 66 tons | 63 tons | |

The crushing plant is fully equipped with track boots. After standing, the electric-hydraulic outrigger extends, and it doesn’t need to manually carry the connecting support seat, automatically and quickly into the operation mode.

Email is required.