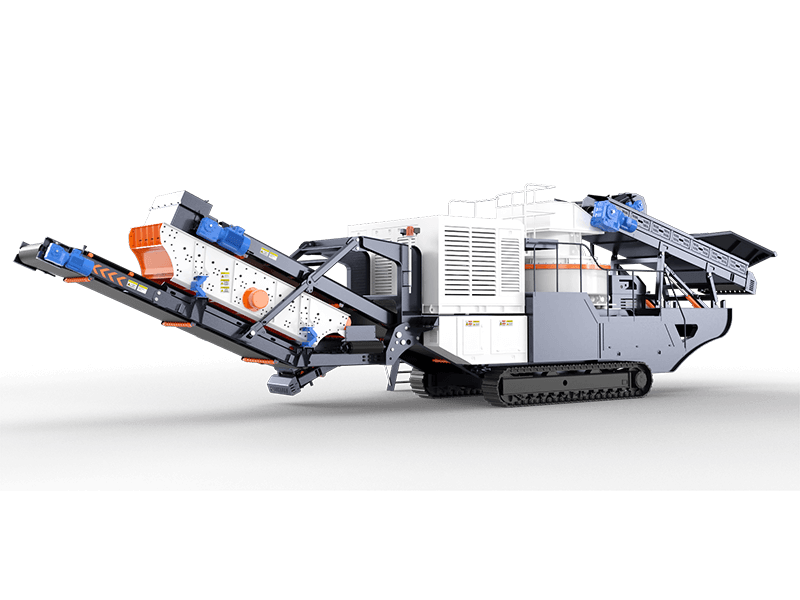

Track-Mounted Mobile Crusher

Capacity: 180-400tph(180-280tph, Center Feeding; 350-400tph, Cascade and Center Feeding)

JEESUNSPOM Track-mounted Sand Making and Screening Plant is a new generation of high-efficiency vertical shaft impact crushing plant launched by our company in order to meet the changing demand for high-quality mechanism sand in the sand and gravel market. It can be used for both shaping and sand making.It can be used for both shaping and sand making. It can be used in combination with other tracked mobile plants or operated independently, It can be used for both shaping and sand making and can be used in combination with other tracked mobile plants or operated independently, and is one of the preferred equipment for producing high-quality aggregates. It can also be used to prepare material for grinding in certain mining operations.

High quality final product. The whole machine has a compact structure and reasonable layout. The main machine has unique design, such as single motor and hydraulic opening device, which has large production capacity and good granularity.

Self-contained vibrating screen with high screening efficiency and flexible adjustment. With its own large vibrating screen, it can sieve the finished products efficiently and precisely; the screening unit can be easily connected or disconnected as required.

Oil-saving power system, saving production costs. The power system of the whole machine adopts an oil-saving power system with low fuel consumption, which can greatly reduce production costs.

Easy to move on site and flexible to change production location. Compared with traditional stationary or portable sand making machines, The WOCATSPOM TVS9532 Track-mounted Sand Making and Screening Plant is more convenient to move and can meet the mobility requirements of users.

The working principle of the fine crushing and sand washing mobile station is the same as that of the impact sand making machine. The material enters into the sand making machine from the feed hopper, and the material is divided into two parts through the distributor, one part of which enters into the high-speed rotating impeller in the middle of the distributor, and is rapidly accelerated within the impeller with an acceleration up to hundreds of times the acceleration of gravity, and then is projected out with a speed of 60-70 metres per second from the impeller within the three evenly distributed runners and is firstly dropped by the distributor around the part of material impact crushing. Firstly, a part of the material falling around the distributor will be impacted and broken, and then impacted to the material lining layer in the vortex cavity, and then rebounded by the material lining layer, and then impacted diagonally upwards to the top of the vortex cavity, and then change its direction of movement, and deflected downwards, and then the material launched out from the impeller channel will form a continuous flow of material.

In this way, a piece of material in the vortex crushing chamber is subjected to two or more times the rate of impact, friction and grinding and crushing effect. The crushed material is discharged from the lower discharge port. It forms a closed circuit with the circulating screening system, and the material can be crushed into less than 20mesh in three cycles. In the whole process of crushing, the materials are crushed by their own impact, not in direct contact with the metal components, but crushed by impact and friction with the material lining, which reduces the pollution and prolongs the life of the machine. The clever self-circulation of airflow inside the vortex chamber eliminates dust pollution.

| Capacity | 180-400tph(180-280tph, Center Feeding; 350-400tph, Cascade and Center Feeding) |

| Maximum feeding size | 45mm (Soft Material); 40mm (Hard Material) |

| Power of sand making machine | 315kw |

| Rotor diameter | 950mm |

| Generator | 520kw |

| Electrical System | PLC intelligent control system |

| Operation weight | 60t |

| Transport Dimensions | Length 20m | Width 3.85m | Height 4m |

| Operation Dimensions | Length 21m | Width 3.85m | Height 5.3m |

With a lower cost per ton than other impact crushing processes and excellent particle size that produces precisely shaped and uniform final products. The product has an excellent particle size and produces a precise and uniform final product with high processing capacity and stable operation, which is very suitable for the production of artificial sand making and stone shaping.

Email is required.