Email:[email protected]

Secondary crushing

In stone handling and construction material processing, medium and fine crushing is an important process to further refine the coarse crushed stone material to meet specific requirements. This process is usually accomplished by impact crusher and cone crusher, which are divided into hydraulic cone crusher and spring-hydraulic cone crusher, each of which has its own specific advantages and applicable scenarios.

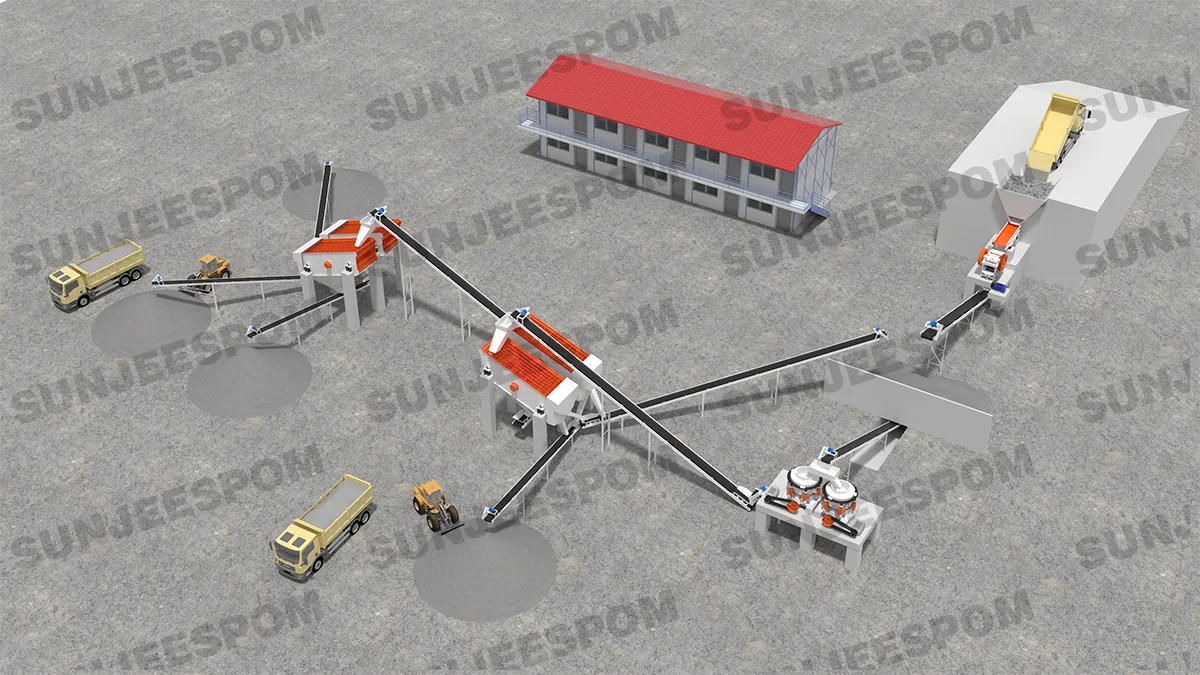

The general configuration of medium and fine crushing production line:

1. Feeder + jaw crusher + impact crusher + vibrating screen

2. Feeder + Jaw Crusher + Cone Crusher + Vibrating Screen

It can be flexibly configured according to the specific stone material.

With its high-speed rotor, the impact crusher utilizes the impact between the stone material and the high-speed movement of the strike plate to carry out crushing. Its advantages are large handling capacity, uniform finished product size, and suitability for various hardness and shape of stone materials. Impact crusher is suitable for crushing medium hardness stone materials, such as limestone, shale and so on.

Cone crusher realizes stone crushing and crushing through the conical crushing chamber and the cone action shaft fixed on it. According to the different power system, cone crusher is divided into two types: hydraulic cone crusher and spring hydraulic cone crusher.

Hydraulic Cone Crusher: The hydraulic system is utilized to drive the adjustment of the discharge opening and crushing chamber of the cone crusher, which can realize precise adjustment and efficient operation. Hydraulic Cone Crusher is suitable for processing medium hardness and high hardness stone materials, such as river pebbles, granite, quartz stone, etc.

Spring Cone Crusher: The spring cone crusher has a simple structure and is more flexible in operation, able to adapt to different hardness and shape of stone materials.

Application Scenarios and Advantages

Impact crusher is suitable for crushing stone with medium hardness, widely used in highway, high-speed railroad, water conservancy project and other engineering fields. While cone crusher is suitable for projects requiring higher crushing ratio and even finished products, such as construction, bridge, cement and gravel processing plant.

Conclusion

As an important step in the process of stone processing, medium and fine crushing needs to choose the appropriate crusher according to the specific engineering requirements and characteristics of stone materials. Impact crusher and cone crusher become indispensable equipment in stone processing industry due to their unique working principle and applicability.