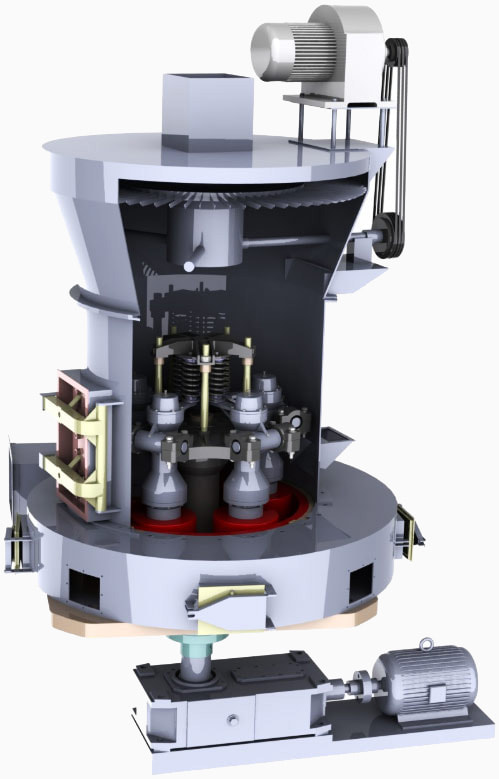

The European Type Grinding Mill is a new type of grinding mill equipment widely used in the market. Our company adopts advanced European design concepts and standards. The grinding mill adopts bevel gear integral transmission, internal thin oil lubrication system, arc-shaped air duct, etc. With a number of patented technologies, it is an replacement product of traditional Raymond mill and pendulum mill. This grinding mill has a compact structure, small footprint, low operating cost and improved production efficiency, widely used in the market.

The European Type Grinding Mill are mainly used in building materials, chemicals, fertilizers, refractory materials, ceramics, steel and other industries. The finished product can be adjusted between 80-600 mesh.

⚫ The bevel gear is integrally driven, with a more compact structure, low energy loss and high efficiency.

⚫ Curved air duct, small air volume loss and good material flow.

⚫ Internal thin oil lubrication system, advanced and reliable.

⚫The curved-surface replaceable blade blade improves grinding efficiency and reduces usage costs.

⚫The particle size of the finished product is adjustable and controllable, and the powder selection efficiency is high.

After jaw crushers break large bulky materials to smaller ones, elevators work to send materials to the hopper. Then, by electromagnetic vibrating feeders, broken materials are evenly and quantitatively sent to the grinding chamber of European Type Grinding Mill. After grinding, materials are blown away by airflow to the powder concentrator for classifying. Under the action of the impeller of powder selector, materials which fail to meet fineness would be sent back to grinding chamber to get another grinding while qualified powders would be collected by cyclone powder collector and discharged from the bottom as finished products. And, after that, the airflow would go into the fan along with the air return duct at the top of cyclone power collector. This system adopts a closed circuit and runs under positive and negative pressure. Because materials have a certain content of moisture, heat generated during grinding may lead air evaporation or swell in the grinding chamber so that the amount of airflow increases sharply. Besides, if the feed port and joints of pipelines are not sealed well, external air may intrude the grinding mill and lead imbalance of airflow. So, SPOM arranges exhaust valves at the air outlet of the fan to induce redundant air into the bag filter. After purifying, the redundant air is discharged. This arrangement can achieve both the balance of airflow and the eco-friendly production.

| Model | ZTM100 | ZTM130 | ZTM140 | ZTM160 | ZTM180 | ZTM190 |

| Grinding rollers(pcs) | 4 | 4 | 4 | 4 | 4 | 4 |

| Roller diameter*height(mm) | Ф360x190 | Ф410x210 | 460x240 | Ф440x270 | Ф520x280 | Ф640x330 |

| Grinding ring diameter*height(mm) | Ф950x190 | Ф1280x210 | 1380x240 | 1600x270 | 1750x280 | 1950x330 |

| Host speed | 132 | 106 | 105 | 92 | 78 | 72 |

| Maximum feed size(mm) | ≤25 | ≤30 | ≤30 | ≤30 | ≤35 | ≤35 |

| Finished particle size(mesh) | 80-600 | 80-600 | 80-600 | 80-600 | 80-600 | 80-600 |

| Capacity(t/h) | 0.5-6.5 | 2.0-14.0 | 3.0-17.5 | 5.0-25 | 6.5-32 | 8.5-40 |

| Dimensions L*W*H(mm) | 7350x5900x7900 | 8000x8550x9700 | 9700x8500x10200 | 9230x10116x10510 | 9368x11500x11000 | 10465x11372x11500 |

| Host motor power(kW) | 37-45 | 75-90 | 90-110 | 132-160 | 185-200 | 220-250 |

| Powder separator motor power(kW) | 5.5-11 | 18.5-22 | 22-30 | 30-37 | 37-45 | 45-55 |

| Induced fan motor power(kW) | 30-37 | 75-90 | 110-132 | 160-200 | 200-220 | 220-250 |

| Dust collector model | DMC36 | DMC36 | DMC48 | DMC64 | DMC96 | DMC96 |

| Dust collector power(kW) | 3 | 3 | 3 | 5.5 | 7.5 | 7.5 |

| Air compressor power(kW) | 4 | 4 | 4 | 5.5 | 7.5 | 7.5 |

| Electromagnetic vibrating feeder model | GZ2F | GZ3F | GZ3F | GZ3F | GZ4F | GZ5F |

| Electromagnetic vibrating feeder power(kW) | 0.15 | 0.2 | 0.2 | 0.2 | 0.45 | 0.65 |

The main engine, fan and powder separator are lubricated with thin oil, without adding oil pump or lubricating station, the main shaft bearing and bevel gear shaft bearing can be lubricated.

Email is required.