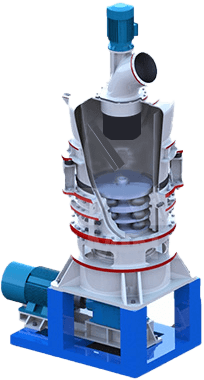

Ultrafine Grinding Mill is mainly suitable for calcite, calcium carbonate, dolomite, talc and other non-flammable and explosive materials with Mohs hardness below 9 and humidity below 6%.

Ultrafine Grinding Mill is a new superfine powder (325-2500 mesh) production equipment developed through accumulating years of experience in grinding mill production, absorbing Swedish advanced machine manufacturing technology, and undergoing many years of tests and improvements. The Ultrafine Grinding Mill is the result of combination of advanced Chinese and Swedish technologies. Meanwhile, it symbolizes the new development and new science in the grinding world.

Best selling machine model

ZSM60、ZSM80、ZSM90、ZSM100、ZSM125、ZSM168

1. The yield is 40% higher than other mills.

2. High utilization rate of Wear material:2-5years.

3. Adjustable particle size:325-3000mesh.

4. High safety and reliability. The design of the mill is rigorous, so no screw loosening to damage the machine.

5. Closed system, so it is the green and ideal equipment for environment protection.

After hammer crushers break large bulky materials to smaller ones, elevator works to send materials to material bin. Next, materials are sent to the grinding mill evenly and they would fall onto the dispersing plate firstly. When the grinding mill runs, dozens of grinding rollers start to rotate and roll. Under the action of centrifugal force, materials on the dispersing plate are then thrown to the rim and drop to the grinding chamber. In the circuit, materials would be squeezed and ground. After being ground several times, materials are blown into the powder selector by airflow. Under the action of the impeller of powder selector, materials which fail to meet fineness would be sent back to grinding chamber to get another grinding while qualified powders would be collected by cyclone powder collector and discharged from the bottom as finished products. Some remaining powders would be collected by impulse dust remover and they may stick to the surface of filler-bag. So, next, high-pressure airflow controlled by the impulse valve blows the filler-bag to make it swell and shake violently. This sudden shake can help kick off materials on the filler-bag and collect them as finished products. After filtering, the airflow would be discharged to the air. This system adopts an open circuit and runs under negative pressure.

| Model | ZSM60 | ZSM80 | ZSM90 | ZSM100 | ZSM125 | ZSM168 | |

| Ring rollers(pcs) | 12 | 21 | 24 | 36 | 44 | 44 | |

| Working diameter(mm) | φ600 | φ800 | φ900 | φ1000 | φ1250 | φ1680 | |

| Number of grinding rings and raceways(pcs) | 1x3 | 1x3 | 2x4 | 2x4 | 2x4 | 2x4 | |

| Host speed(r/min) | 230-240 | 230-240 | 200-220 | 180-200 | 135-155 | 120-130 | |

| Maximum feed size(mm) | ≤10 | ≤10 | ≤20 | ≤20 | ≤20 | ≤20 | |

| Finished particle size(mesh) | 325-2500 | 325-2500 | 325-2500 | 325-2500 | 325-2500 | 325-2500 | |

| Capacity (kg/h) | 300-3000 | 500-4500 | 800-6500 | 1000-8500 | 2500-14000 | 5000-25000 | |

| Feeding machine | Type | Skirt belt feeder | Skirt belt feeder | Skirt belt feeder | Skirt belt feeder | Skirt belt feeder | Skirt belt feeder |

| Type | B300x60 | B300x60 | B300x60 | B300x60 | B300x80 | B400x80 | |

| Power(kW) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Host | Power(kW) | 45 | 55 | 45x2 | 132 | 185 | 315 |

| Powder separator | Power(kW) | 15 | 18.5 | 22 | 30 | 75 | 132 |

| Dust collector | Type | DMC96 | DMC160 | LDCM35-7 | LDCM35-8 | LDCM72-8 | LDCM72-8x2 |

| Power(kW) | 37 | 45 | 55 | 75 | 132 | 220 | |

| Discharge screw | Power(kW) | - | 3 | 3/5.5 | 7.5 | 7.5 | 7.5x2 |

| Discharge valve | Power(kW) | 0.75x2/0.75x1 | 0.75x1 | 1.1x1 | 1.5x1 | 1.5x2 | 1.5x2 |

| Air compressor | Power(kW) | 7.5 | 11 15 | 15 | 22 | 37 | 55 |

| Gross weight(t) | 12.5 | 16.5 | 24.6 | 32.2 | 54 | 76 | |

| Dimensions(mm) | 12000x4500x6000 | 14000x4700x6200 | 14700x4800x8600 | 18000x4600x8600 | 14000x9000x10250 | 26300x7500x11900 | |

Newly designed grinding curves of grinding roller and grinding ring further enhance the grinding efficiency of SCM Ultrafine Grinding Mill. With the same fineness and power, the production capacity is 40% higher than that of jet grinding mill and stirred grinding mill, and the yield is twice as large as that of ball grinding mill. However, the system energy consumption is only 30% of the jet grinding mill.

Email is required.