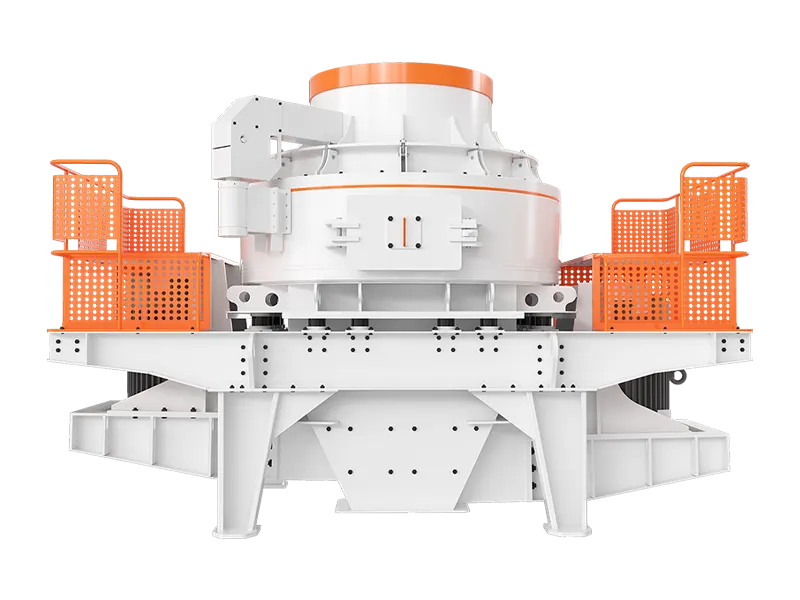

Crushing and Sand Making Equipment

Feeding Size: ≤50mm

Capacity: 120-520t/h

The VSI series sand making machine is a high-performance sand making equipment with international advanced level developed and produced by introducing advanced German technology. Its performance plays an irreplaceable role in various types of ore fine crushing equipment. The sand making machine is an important tool for artificial sand making and stone shaping. The primary equipment in the field. First, sand making function. The new sand making machine (vertical shaft impact crusher) is suitable for crushing soft, medium hard, and extremely hard ore materials with a hardness not higher than 320Pa. Second, the shaping function. The stones are accurately shaped and finely processed by our VSI series sand making machine. Using the stone-on-stone working principle, the final product can be produced with high quality and uniform particle size, making the product better in shape.

1. Artificial sand making of river pebbles, mountain rocks (limestone, granite, basalt, gabbro, andesite, etc.), ore tailings, stone chips.

2. The production of construction aggregate, highway road surface material, bedding material, asphalt concrete and cement concrete aggregate.

3. Machine-made sand production and stone shaping for water conservancy and hydropower, high-grade highway, highway, high-speed railroad, passenger dedicated line, bridge, airport runway, municipal engineering, high-rise building in engineering field.

4. Fine crushing process in the field of mining before milling, material crushing in the industries of building materials, metallurgy, chemical industry, mining, refractory materials, cement and abrasive materials.

1. High efficiency and high energy saving, high crushing efficiency. Large handling capacity, high output, cubic products, good particle shape, well-graded, adjustable fineness modulus, especially suitable for artificial sand and stone shaping, compared with the same power of the traditional equipment, the output increased by 30%.

2. It has the functions of fine crushing and coarse grinding.

3. The crushing material passing rate is high. Small influence by material moisture, water content up to 8%.

4. Oil lubrication, automatic maintenance. Adopting German original oil lubrication station, double oil pumps complement each other to ensure oil supply, no oil leakage, automatic shutdown when there is no oil pressure; oil cooling and heating device to ensure that the bearing lubrication is always in a good state, thus completely solving the problem of bearing heat, so that the spindle bearings to maintain a constant temperature, prolonging the maintenance intervals and service life.

5. Various feeding methods can be converted. It is convenient to realize the conversion between the two feeding methods of complete center feeding and center feeding accompanied by waterfall feeding, and also convenient to realize the conversion of "stone hitting stone" and "stone hitting iron", which makes the machine multi-purpose to adapt to the requirements of different users such as stone crushing and shaping.

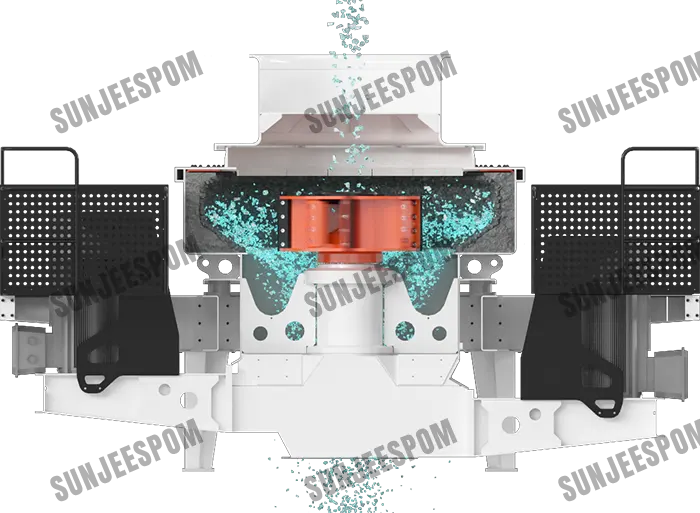

VSI Sand Making Machine uses high-speed moving materials to crush each other and the friction between materials. The material falls into the feeding hopper of the sand making machine, enters the high-speed rotating wheel through the central feeding hole, is rapidly accelerated in the wheel, and its acceleration can reach dozens of times the acceleration of gravity, and then is ejected from the wheel at high speed. Another part of the material that falls freely after the rebound hits, and then hits the material lining (stone hits stone) or counterattack block (stone hits iron) together, and is rebounded and hits the top of the vortex chamber obliquely upward, and then changes its movement direction, deflecting to It moves downward and collides with the material emitted from the impeller channel to form a continuous material curtain. In this way, a piece of material is subjected to two or more chance impacts, friction and grinding and crushing in the eddy current crushing chamber, and the crushed material is discharged from the lower discharge port.

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI1140 | |

| Capacity(t/h) | Cascade and center feeding | 120-180 | 200-260 | 300-380 | 450-520 |

| center feeding | 60-90 | 100-130 | 150-190 | 225-260 | |

| Feeder opening size(mm) | Soft material | ≤35 | ≤40 | ≤45 | ≤50 |

| Hard material | ≤30 | ≤35 | ≤40 | ≤45 | |

| Rotation speed | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | |

| Power of the double motors(kw) | 110-150 | 180-220 | 264-320 | 400-440 | |

| Overall dimension(mm) | 3700x2150x2100 | 4140x2280x2425 | 4560x2447x2778 | 5000X2700X3300 | |

| Weight(t) | 7.8 | 10.3 | 16 | 25.6 | |

| Power | 380V:50Hz | ||||

| Vibrating sensor | Inspection Scope: 0.1-20mm/s,it can be adjusted continuously | ||||

| This oil lubrication station | Power of double oil pump | 2x0.31kw | |||

| safety | supply of oil; Stop automatically without oil flow or oil pressure; Water cooled; Heating start the motor in winter | ||||

| Overall dimension(mm) | 820x520x1270 | ||||

| Power of oil-box heater dimension(kw) | 2KW | ||||

It is the key equipment for artificial sand making to provide high quality sand aggregate for building, highway, construction, concrete batching plant, etc.

Email is required.