Crushing and Sand Making Equipment

Feeding Size: ≤10mm

Capacity: 30-160t/h

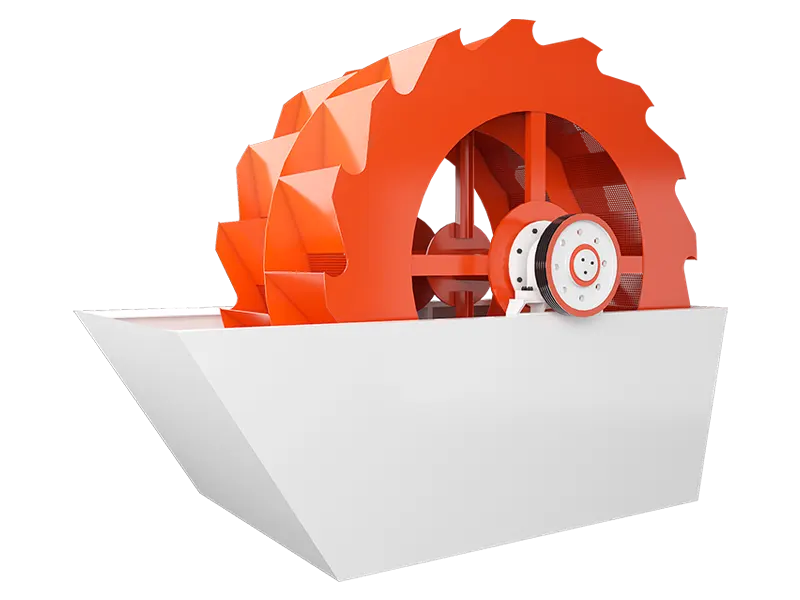

The sand washing machine adopts advanced technology and is a high-efficiency sand washing equipment developed in combination with the actual situation of the domestic sand and gravel industry. It has high washing height, reasonable structure, large output, and less sand loss during the sand washing process, sand isolation, so its failure rate is much lower than the current commonly used sand washing machine, it is the choice for upgrading the domestic sand washing industry. The Shibo sand washing machine adopts special manufacturing materials, which can resist wear and corrosion, so that it can operate normally in any harsh environment and greatly prolong its service life; in addition, the energy saving effect of the sand washing machine is also very significant.

Our sand washer/sand washing machine includes two types for choice: bucket wheel type sand washing machine (XS series) and screw/spiral sand washing machine.

Sand washer/sand washing machine (sand washing and sieving machine) is the commonly used equipment in artificial sand making production line. It is widely used to process silica sand, river sand, yellow sand, sea sand, etc. It is used to remove the dirt and impurities in sand for sand washing, classifying and grading to meet the standard.

Reasonable structure and stable production

Novel sealing structure, fully enclosed oil bath transmission device, and adjustable overflow weir plate ensure that this series of products are durable, have good cleaning and dehydration effects, and maintain stable fine-grained products.

Scientific design, low failure rate

This machine adopts the design of the impeller drive bearing device and the water and material separately, to avoid the damage caused by the premature pollution and rust of the machine, so its failure rate is much lower than other commonly used sand washing machines.

Fewer wearing parts and low cost of use

Except for the screen, the machine has almost no wearing parts, and needs maintenance in rare cases, so the use cost can be greatly reduced.

Less loss, high clarity, and grading standards

The washed materials have high cleaning degree and no pollution, and the loss of medium and fine sand and stone powder is very small.

When the sand washing machine is working, the motor drives the impeller to rotate slowly after being decelerated by the V-belt and the reducer gear. At the same time, the water vapor layer covering the sand grains is destroyed to facilitate dehydration; at the same time, water is added to form a strong water flow, which can promptly take away impurities and foreign objects with small specific gravity, and discharge them from the overflow port washing tank to complete the cleaning effect. The clean sand and gravel are taken away by the blades, and the sand and gravel are poured into the discharge trough from the rotating impeller to complete the cleaning of the sand and gravel.

| Model | Impeller(mm) | Feeding Size(mm) | Capacity(t/h) | Power(kw) | Overall Dimension(mm) |

| XSD2610 | Ф2600 | ≤10 | 30-60 | 7.5 | 3320x2125 ×2670 |

| XSD2900 | Ф2900 | ≤10 | 50-90 | 15 | 3810x2686x3085 |

| XSD3016 | Ф3000 | ≤10 | 80-120 | 18.5 | 3845x3000x3080 |

| XSD3220 | Ф3000 | ≤10 | 120-200 | 22 | 4150x3780x3400 |

| XSD3620 | Ф3600 | ≤10 | 150-280 | 30 | 4600x3780x3900 |

Sand washer/sand washing machine (sand washing and sieving machine) is the commonly used equipment in artificial sand making production line. It is widely used to process silica sand, river sand, yellow sand, sea sand, etc. It is used to remove the dirt and impurities in sand for sand washing, classifying and grading to meet the standard.

Email is required.